Research

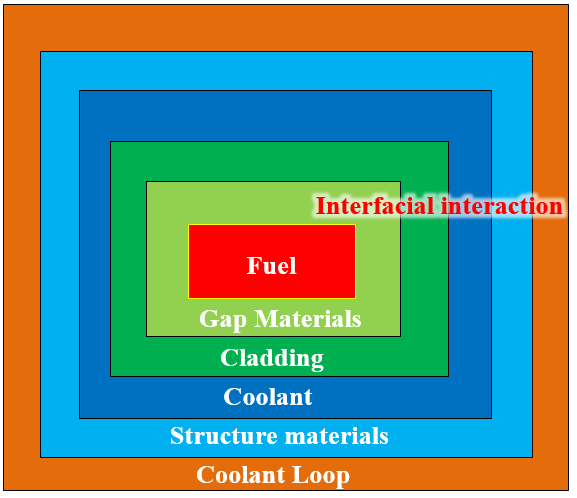

1. Materials Compatibility :

- Between Fuel and Coolant

- Fuel-coolant chemical reactions, source term release from fuel to coolant

- Between Fuel and Cladding

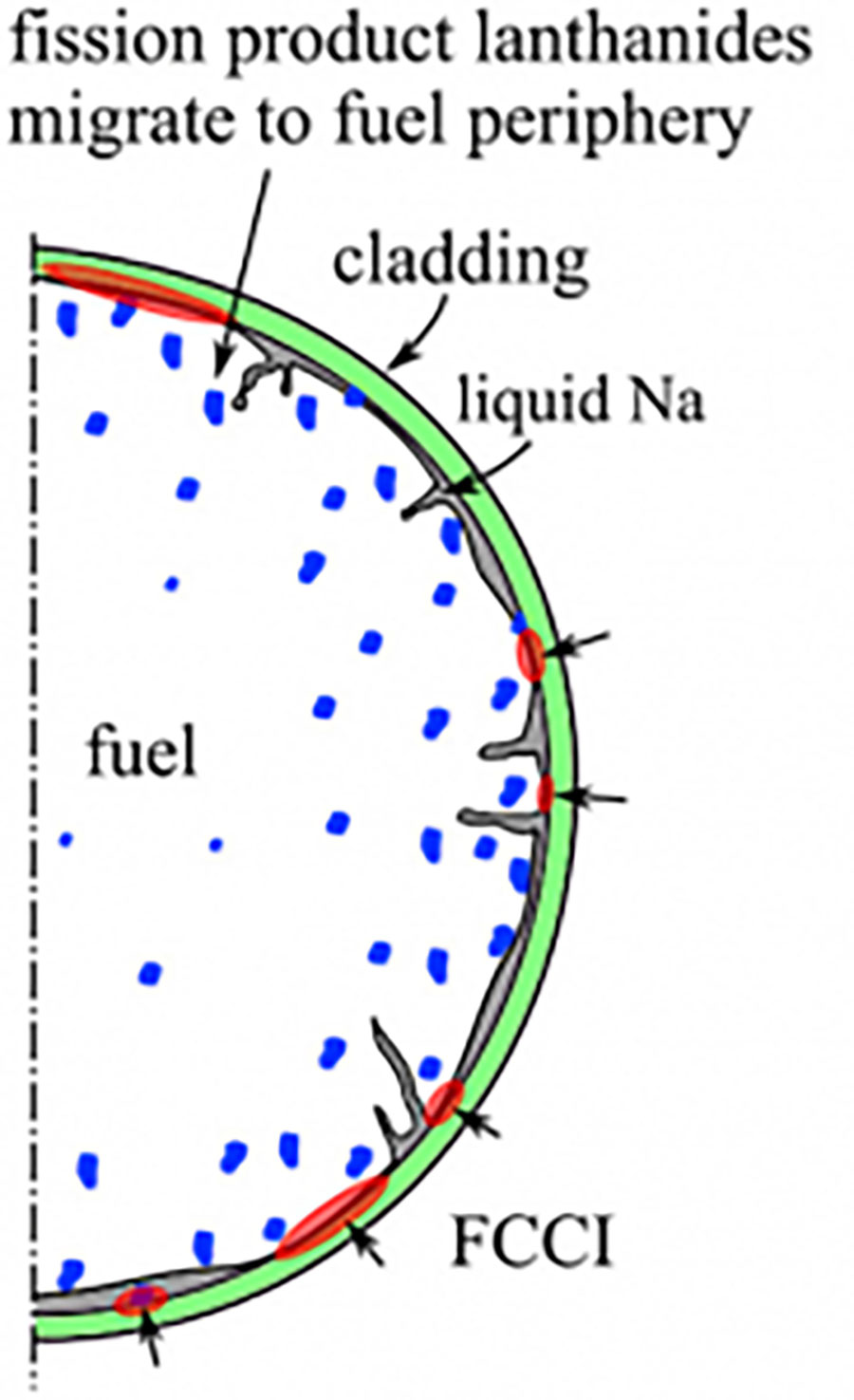

- Fuel-cladding chemical interaction (FCCI) is one of the major cladding degradation of advance metallic fuel because of the chemical reactions between nuclear fuel/fission products and stainless steel cladding

- Between Coolant and Cladding/Structural Materials

- Material degradation and corrosion by coolant, for example, Nickel-based alloys can not be used as structrural materials for liquid-lead/lead-bismuth-cooled reactor because the high solubility of Ni in the liquid metal/alloy

- Between Fuel Pin Gap materials and Fuel

- Liquid lead can not be used as gap material for oxide fuel, because of the transfer of oxygen

2. Nuclear Fuel Cycle :

- Used Fuel Dry Storage

- Canister degradation, cladding hydrogen embrittlement

- Electrochemical Separation

- Used Metal fuel, oxide fuel and nitride fuel treatment

- Molten salt reactor (MSR) on-line purification

- Coolant impurity removal

- Advanced Nuclear Coolant Chemistry Control

- Oxygen control in Liquid metal, Redox control in molten salt

3. Nuclear Coolants:

- Liquid metal (Na, Pb, Pb-Bi)

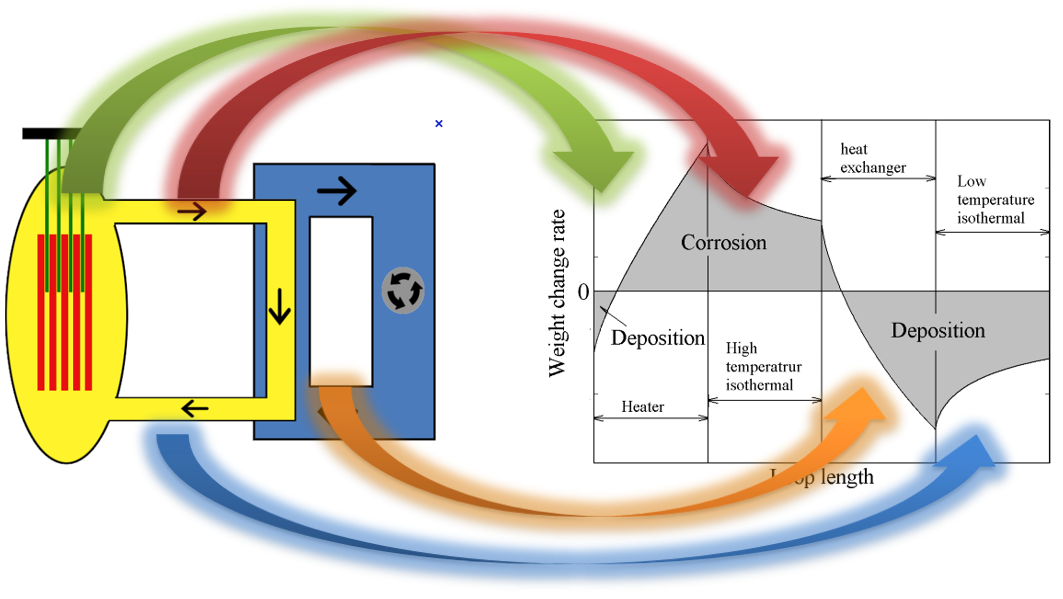

- Corrosion (loop global corrosion, local corrosion, etc)

- Interactions with fuel (Material release from the fuel)

- Chemistry control (oxygen control)

- Source term release (solubility measurement, thermodynamic properties, transport in the coolant, retention capability)

- Molten Salt (Chloride Salts, Fluoride Salts)

- Corrosion (corrosion mechanisms, materials transport)

- Physical properties (density, viscosity, etc)

- Chemistry control (fission products chemistry, redox control)

- Source term release (fission product properties, retention capability)

- High-temperature Water

- Stress corrosion cracking

- Water-fuel interaction

4. Fuel Materials:

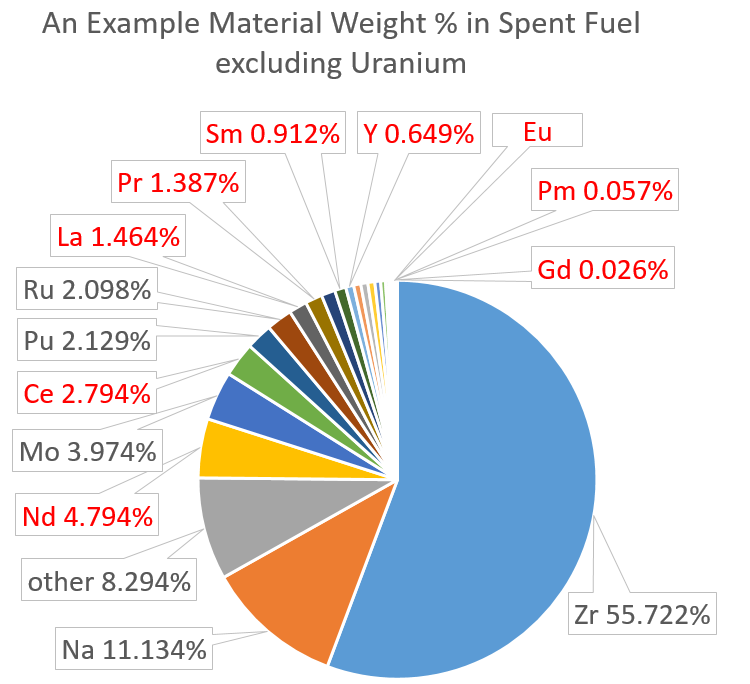

- Metal Fuels (U-Zr)

- Interactions with coolant (source term release)

- Fuel-cladding-Chemical interactions (FCCIs)

- New fuel alloy development (adding additives for mitigating FCCIs)

- Pyroprocessing used metal fuels

- Nitride fuel

- Interactions with coolant

- Pyroprocessing used nitride fuels

- Oxide fuels

- Interactions with coolant

- Source term release

- Novel cladding materials development (MMLC) for accident to tolerant fuels